Magnetic Strip Rulers Market Size

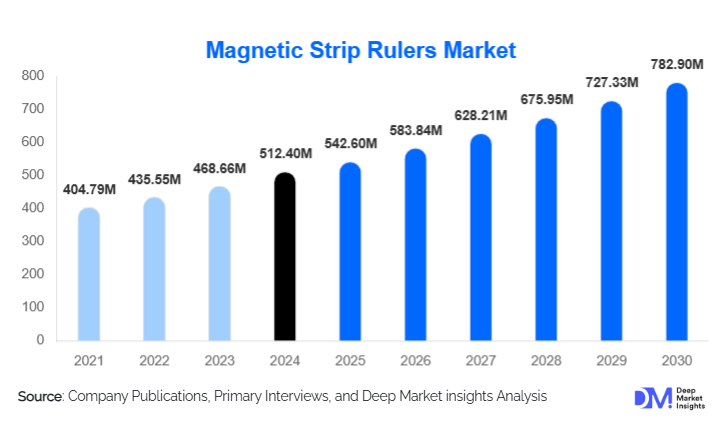

According to Deep Market Insights, the global magnetic strip rulers market size was valued at USD 512.4 million in 2024 and is projected to grow from USD 542.6 million in 2025 to reach USD 782.9 million by 2030, expanding at a CAGR of 7.6% during the forecast period (2025–2030). The growth of the magnetic strip rulers market is primarily driven by the rising demand for precision measurement tools in manufacturing, the increasing adoption of magnetic measurement technologies across industrial automation, and the growing popularity of advanced metrology solutions in engineering and R&D applications.

Key Market Insights

- Precision engineering and smart manufacturing are major drivers, increasing the integration of magnetic strip rulers in CNC machines, coordinate measuring systems, and robotic assemblies.

- Growing automation in the automotive and aerospace sectors is fueling the adoption of high-accuracy magnetic position and length measuring systems.

- Asia-Pacific dominates the global market due to rapid industrial expansion in China, Japan, and South Korea.

- Europe remains a hub for innovation, with strong R&D investments in precision metrology and sensor integration technologies.

- Miniaturization and digital readout advancements are enhancing usability across laboratories, electronics assembly, and quality inspection processes.

- Emerging applications in renewable energy and robotics are broadening the market’s technological landscape.

Latest Market Trends

Integration of Magnetic Rulers with Digital Readouts

Manufacturers are increasingly developing digital-ready magnetic strip rulers compatible with advanced linear encoders and DRO (Digital Readout) systems. This integration enhances real-time feedback in machining centers, laboratories, and production floors. The trend toward smart factories is boosting demand for such interconnected systems, enabling precise, automated, and data-driven measurement operations. The use of wireless communication modules and IoT-enabled magnetic rulers further supports remote monitoring and predictive maintenance in industrial environments.

Adoption of Non-Contact Measurement Systems

Non-contact magnetic measurement systems are gaining popularity due to their high durability, reliability, and suitability for harsh industrial conditions. These rulers eliminate issues like wear and tear found in mechanical scales, ensuring long-term accuracy even in dusty, oily, or vibrating environments. The trend aligns with the industry’s shift toward maintenance-free and cost-efficient metrology tools, particularly in sectors such as semiconductors, packaging, and metal processing.

Magnetic Strip Rulers Market Drivers

Growing Demand from Industrial Automation

The expanding use of automation in manufacturing and processing industries is driving demand for precision measurement tools that ensure high accuracy and repeatability. Magnetic strip rulers play a crucial role in machine calibration, position feedback, and motion control systems in industries such as automotive, electronics, and heavy machinery. Their ability to deliver precise linear measurements under high-speed and high-vibration conditions makes them indispensable in automated production environments.

Rise in Adoption of Smart and Digital Measuring Tools

The shift from analog to digital metrology systems is another significant market driver. End-users are increasingly adopting digital magnetic strip rulers for their superior data integration capabilities, user-friendly operation, and connectivity with CNC systems and PLCs. The growing preference for real-time measurement feedback and data logging for quality control purposes further amplifies market growth, especially in industrial R&D and testing laboratories.

Market Restraints

High Initial Costs and Integration Challenges

The installation and integration of magnetic rulers with existing systems can be expensive, especially for small and medium-scale manufacturers. Compatibility issues between magnetic sensors, encoders, and control systems can also add to setup complexity. Moreover, the high cost of precision-grade materials used in ruler construction limits widespread adoption across cost-sensitive industries such as consumer electronics assembly and small-scale workshops.

Performance Limitations in Extreme Environments

Although magnetic strip rulers are designed for industrial robustness, their performance can be affected by strong external magnetic fields, temperature fluctuations, or high humidity. These factors can influence measurement accuracy and long-term stability. Consequently, industries operating in harsh environmental conditions may face challenges in maintaining consistent performance without protective enclosures or specialized calibration systems.

Market Opportunities

Expansion in Robotics and Renewable Energy Sectors

As robotics and renewable energy systems demand high-precision motion control, magnetic strip rulers are finding new applications in solar tracking systems, robotic arms, and wind turbine blade alignment. The increasing focus on automation in clean energy and sustainable industries offers significant potential for market expansion. The integration of magnetic encoders with AI-driven predictive maintenance systems is also opening opportunities for innovation and differentiation among leading manufacturers.

Development of Miniaturized and Flexible Magnetic Rulers

Miniaturized magnetic rulers designed for compact devices and flexible substrates are emerging as key innovation areas. These solutions cater to electronics assembly, biomedical instrumentation, and laboratory-scale applications where space constraints demand thin, lightweight, and flexible measuring systems. This technological evolution is expected to drive product diversification and open niche opportunities in precision micro-engineering and semiconductor manufacturing.

Product Type Insights

The magnetic strip rulers market is segmented by product type into Incremental Magnetic Rulers and Absolute Magnetic Rulers. Incremental rulers dominate the market due to their cost-effectiveness and simplicity, offering reliable measurement feedback for linear motion systems. However, absolute magnetic rulers are gaining traction for their ability to retain position data even after power interruptions, making them ideal for automation, robotics, and machine tool applications requiring uninterrupted precision.

Application Insights

Key application segments include Machine Tools, Industrial Automation, Robotics, Aerospace, Automotive, and Electronics. The machine tools segment accounts for the largest share, driven by widespread use in CNC machinery, cutting systems, and milling operations. The robotics segment is expected to witness the fastest growth, propelled by the increasing use of compact and high-resolution measurement systems for robotic arm positioning, motion calibration, and precision assembly tasks.

End-User Insights

Major end-users of magnetic strip rulers include Manufacturing Industries, Research & Development Labs, Engineering Design Units, and Quality Control Facilities. The manufacturing sector dominates due to the growing need for precision in automated production lines. R&D labs are increasingly adopting advanced magnetic rulers for prototyping, dimensional analysis, and experimental metrology, supporting innovation in product development and mechanical testing.

| By Product Type | By Application | By End User |

|---|---|---|

|

|

|

Regional Insights

Asia-Pacific

Asia-Pacific leads the global magnetic strip rulers market, with major contributions from China, Japan, and South Korea. The region benefits from a strong industrial base, expanding semiconductor and electronics manufacturing, and growing investments in automation technologies. China remains a key manufacturing hub, while Japan’s precision engineering ecosystem continues to push innovations in magnetic metrology and sensor technologies.

Europe

Europe represents a mature market characterized by advanced manufacturing infrastructure and a strong emphasis on quality control and precision engineering. Germany, Italy, and the U.K. are major contributors, hosting prominent machine tool manufacturers and metrology companies. European initiatives promoting Industry 4.0 adoption are expected to sustain demand for high-end magnetic measurement solutions.

North America

North America holds a substantial share due to the growing adoption of digital manufacturing, automation, and robotics technologies. The United States remains a key market, supported by the presence of major aerospace, automotive, and industrial equipment manufacturers. Ongoing technological integration and R&D in smart factory applications are further bolstering market growth.

Latin America

Latin America is experiencing gradual growth, driven by industrial modernization in Brazil and Mexico. The adoption of precision measurement systems is increasing in manufacturing and automotive industries, supported by foreign investments and government incentives aimed at enhancing production efficiency and competitiveness.

Middle East & Africa

The Middle East & Africa are emerging markets, with increasing focus on establishing regional manufacturing and engineering capabilities. The UAE and Saudi Arabia are investing in industrial automation and digital infrastructure, while South Africa is witnessing growth in automotive and aerospace applications that rely on advanced measurement tools.

| North America | Europe | APAC | Middle East and Africa | LATAM |

|---|---|---|---|---|

|

|

|

|

|

Key Players in the Magnetic Strip Rulers Market

- Renishaw plc

- RSF Elektronik GmbH

- Fagor Automation

- Gurley Precision Instruments

- Mitutoyo Corporation

- Heidenhain GmbH

- Magnescale Co., Ltd.

- SIKO GmbH

- ELGO Electronic GmbH & Co. KG

- Baumer Group

Recent Developments

- In May 2025, Heidenhain GmbH launched a new series of compact magnetic strip encoders with enhanced temperature stability for machine tool and semiconductor applications.

- In April 2025, Renishaw plc introduced an IoT-enabled measurement platform integrating magnetic rulers with wireless data transmission for real-time monitoring in smart factories.

- In January 2025, Fagor Automation expanded its product line with high-resolution magnetic rulers designed for advanced robotics and precision CNC systems.